ENGINEERING RESOURCES

TUTCO Sets the Bar On Quality Standards

At TUTCO Heating Solutions Group, quality is a cornerstone of our operations. Our Quality Team, based in Cookeville, Tennessee, ensures that our products consistently meet the highest standards. Comprising seven full-time professionals with over 104 years of combined experience, the team excels in Quality Engineering, Quality Planning, APQP, and Reliability Testing. Our efforts to continually […]

TUTCO Solution is a Sign of Things to Come

TUTCO received a request from one of our customers that involved manufacturing equipment designed for a thermoforming process. The customer needed a heating solution for heating sheets of plastic, enabling them to be pressed into signs with precision. Crucially, the plastic had to be heated uniformly to achieve the desired outcome. Uneven heating would lead […]

Moisture. It’s Bad for Your Electric Heater and What You Can Do About It.

Moisture can have a very negative effect on process heaters and their applications, sometimes leading to violent heater failure. It’s important to know effective solutions to safeguard your equipment, as discussed in the latest Ask Ian.A typical heater won’t fare well in a moist environment. They’re not normally built to withstand the ingress of water […]

Cartridge Heater Length-How to Specify Them

When it comes to describing cartridge heaters, some details can be more complex than others. This article aims to resolve any difficulties you may encounter when describing the length of heaters with elbows, right-angle leads, bushings, or other terminations. Here’s the bottom line: If you can see the sheath, measure it, and nothing more! Specifying […]

Researchers Like Their Findings with TUTCO

TUTCO frequently receives inquiries from college students, professors, research personnel at R&D facilities, and scientific research facilities seeking heat source solutions for specialized testing. The requirements vary, with some needing conductive heat sources while others require convective heat sources. In most cases, these customers only require a low volume of heaters. To meet the diverse […]

Why Do Our Heaters Have an Upper Temperature Limit?

One of our readers recently wrote in to ask why heaters have an upper temperature limit. Great question. While there are many factors that determine a heaters upper temperature limit, understanding temperature limitations in a heater is essential for maximizing heater performance and ensuring safety. Electric heaters are limited in temperature by the properties of […]

The Perfect Heater for a Blown Film Application

A blown film manufacturer approached TUTCO with a unique requirement for special machined heater assemblies to be used in a specific process that did not have common off-the-shelf options. The challenge was to find heaters that could fit within a very limited space, ruling out the possibility of using cast heaters due to their space-consuming […]

Stainless Steel Temperatures and Colors

Stainless steel and its related superalloys are exceptional materials known for their resistance to rust, particularly when operating at room temperature or below. However, their resistance to oxidation diminishes when exposed to heat, although they still exhibit impressive resistance. This is why stainless steel and incoloy are preferred materials for the outer sheaths of our […]

An Eye-Popping Heating Solution from TUTCO

TUTCO Heating Solutions Group found itself at the forefront of innovation when a customer, grappling with a challenge in the design of their large popcorn kettles, turned to us for a solution. The challenge lay in the intricate arrangement of multiple cast ring heaters within the kettles used in their popcorn production which, while effective, […]

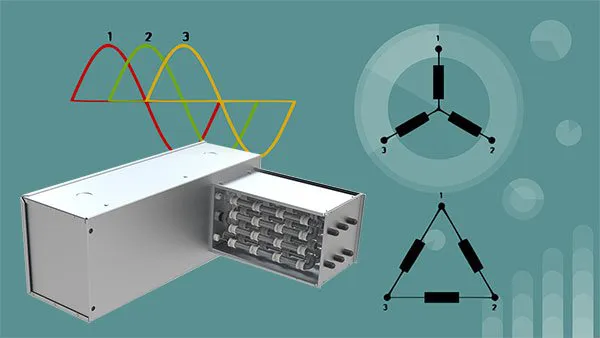

3 Phase Power Systems and How to Know That You Have Wired Them Correctly

There are countless articles on-line describing the two varieties of 3-phase power systems and why one is more beneficial over the other based on your application. The 3-phase systems are called 3-phase delta and 3-phase wye and this document will explain how to connect your single phase heaters to such a system, and more importantly, […]

Honey Application Finds Sweet Solution with TUTCO

TUTCO was approached by a customer with a unique requirement for heaters to be integrated into portable equipment designed for honey harvesting in remote areas where beekeepers manage their hives. The primary goal was to optimize the performance of the working tools used during honey harvesting. In response to this specific need, TUTCO engineered a […]

How to calculate wattage requirements quickly

When you need to determine the wattage required to heat an application, you can delve into some nitty-gritty details when it comes to calculating that number. If you have a good temperature controller, you’re safe to overestimate that number and still be okay, resulting in a system that reaches the desired temperature without the need […]

Automotive application cleans up with TUTCO

A customer in the automotive industry sought a heating solution for their machined components manufacturing process, which involved immersing parts in four distinct tanks containing varied solutions: an etching acid solution, a neutralizing base, a chemical wash, and a mild detergent rinse. The challenge lay in finding a heater that could safely and effectively operate […]

Home brewer sees the proof in TUTCO solution

TUTCO received an interesting request from a customer seeking a heating solution for their home brew moonshine steel kettle to optimize the distilling process. The customer required a band heater that could effectively add heat to the kettle while operating on a standard 120V wall outlet. It was crucial for the heater to be protected […]

All About Tolerances in Conductive Heaters

There are normal variations in the dimensions and electrical properties of heaters we build, and it’s good to know what they are so there are no surprises. First, a few words about tolerances in general. Tolerances are deviations from nominal values, be they lengths or resistance values, in the case of our heaters, that are […]

Difference between distributed wattage heaters, zoned heaters, and dual voltage heaters

TUTCO can provide a wide variety of heater options for many of our product lines. Some of those lesser known but very useful options are distributed wattage heaters, zoned heaters, and dual voltage heaters. They allow for better performance and better control over heaters so you can get the most out of them. Distributed Wattage […]

Customer looks for TUTCO brand solution

TUTCO received a unique request from a customer seeking tubular heating elements for electric branding irons designed for wood and leather applications. However, the challenge was that they required these heating elements to be purchased in multiple straight lengths and subsequently formed with tight bends using hand tools. This bending process introduced the risk of […]

Journey through temperature scales: from Fahrenheit to Kelvin and beyond

Measure temperature and the use of temperature scales have played a pivotal role in human history, aiding in scientific discoveries, technological advancements, and everyday life. Over the centuries, various temperature scales have been developed, each with its unique origin and applications. In this article, we will explore four different temperature scales, Fahrenheit, Celsius, Kelvin, […]

That’s some quality H₂0 – a feel good story

WAPIs for the World, a non-profit company, approached us seeking cartridge heaters for their manufacturing process, which involved building a water purification capsule. This capsule consists of a specially formulated wax enclosed in a tube, designed to melt at a specific temperature, thereby purifying water by eliminating harmful substances. The end-use product is not sold […]

TUTCO provides cure for changes in automotive application

An automotive customer had an issue with a heater they were using in a curing oven where the application required using a liquid mist on a new material they were curing. The original oven manufacturer, who was using a TUTCO open-coil heater suggested the customer speak to us directly to see if we had a […]

The use and proper mounting of strip heaters

TUTCO offers four different types of strip heaters suitable for various applications. Ultima Strip Heaters utilize a reliable tubular heating element encased in a stainless-steel sheath. Withstanding corrosive and high-temperature environments (up to 1200 °F / 648 °C), they are suitable for demanding applications. Offering higher watt densities, faster heat-up times, and longer service life […]

Heater leadwire failure & how to reduce its occurrence

by Ian Renwick – Heating elements are a critical component in various industrial applications, and their reliable performance is essential for smooth operations. However, one common issue that can lead to premature failure of heating elements is leadwire failure. Understanding the causes of leadwire failure and implementing preventive measures can significantly extend the lifespan of […]

Aluminum extruder softens up to TUTCO heating solution

A company near our manufacturing facility came to TUTCO needing a solution for a tubular heater used in an aluminum extruder barrel to keep the aluminum soft enough to press and extrude but not hot enough to make the aluminum a molten liquid. This was a very high-temperature application which resulted in limitations on which […]

Understanding the Difference between Single-Phase AC Power, DC Power, and Three-Phase AC Power

by Ian Renwick – In the world of electrical engineering, power distribution systems rely on various forms of electrical power to meet different requirements: single-phase AC power, DC power, and three-phase AC power. Each type has its own characteristics and uses. Let’s explore their differences and similarities. Single-phase AC power is the most common type […]

It’s all in the soup thanks to a TUTCO heating solution

An entrepreneur was opening a portable food service business which would be serve customers from a food truck and occasionally need to be set up at indoor events. One of their main offerings is a line of soups that needed to be prepared beforehand but needed to be kept warm in a large kettle. A […]

Trucking application shifts to TUTCO custom solution

An existing customer needed a new solution for heat in a custom HVAC system used in an agriculture transport trailer that required the temperature to be controlled in a certain range. The heaters would operate in a custom under floor custom air duct and would need to able to withstand an FDA approved wash […]

Thermal Expansion, Friend or Foe?

by Ian Renwick – Thermal Expansion is the propensity of solid matter to increase its volume when heated. This change in volume occurs in all directions of an object in length, width, and height. The amount of change is proportional to the change in temperature, the initial dimensions of the object and by material itself.Thermal expansion […]

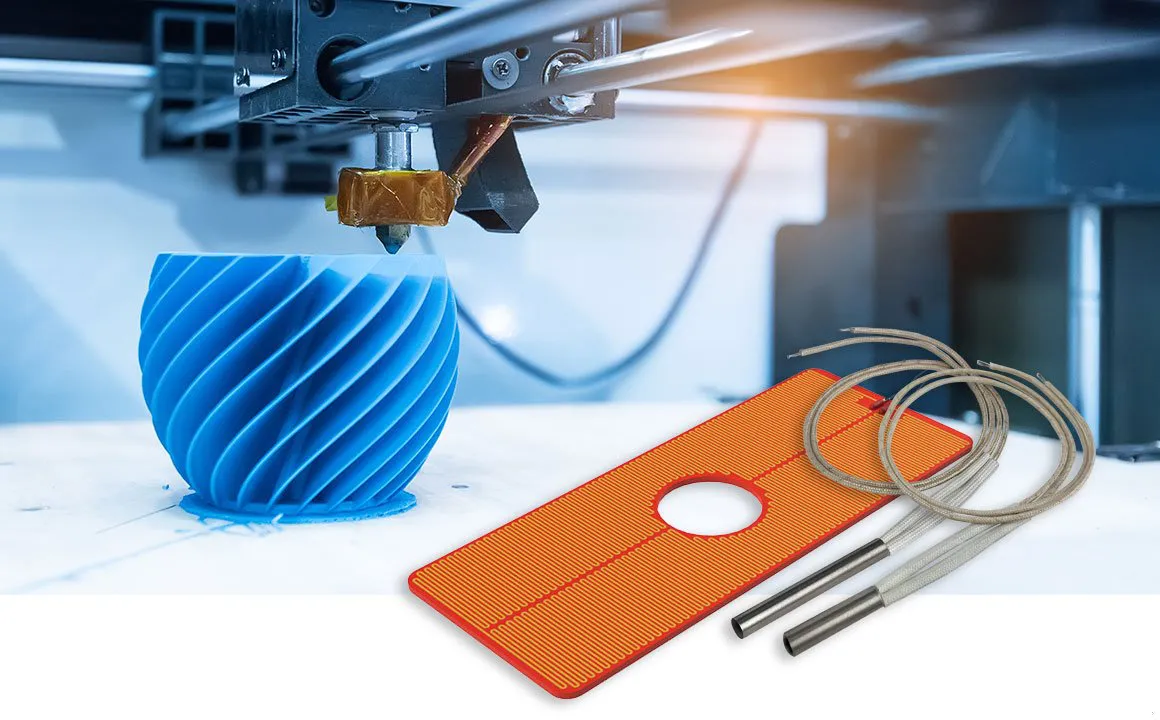

3D printing technology requires specific heaters and sensors

As 3D printing have evolved, a variety of technology and techniques have been used to improve the quality of printed objects. One such technology is the use of specific heaters and sensors within the printer that play a critical role in the success of the process. TUTCO cartridge heaters, as small as 1/4” to 1/8” […]

Mass transit company gets on board with TUTCO

Public transportation vehicles often have small heaters under the seats for passenger comfort. One mass transit company, that was renovating their older passenger cars, came to TUTCO needing a small lightweight heater for this application. Many of the existing heaters, which had been in place for years, had failed and the company that originally built […]

TUTCO HT Mica Band Heater Fits Textile Manufacturer Nicely

A high-volume garment manufacturer using a large heated fabric press to mold and form accessories faced a challenge with the Mica Band heaters used in the press. Downtime was an issue as they had no spare parts heaters on hand and the company that manufactured the press, as well as the heaters, was not […]

Preventing Heater Failure

Understanding the causes of heater failure will extend the life of your heater and ensure that it is working as efficiently as possible. There are three main culprits to be on guard for: physical abuse, application issues, and excessive temperature, any one of which can cause your heater to quickly fail.Physical abuse can easily occur […]

Making Sense of Delta & Wye

By Drew MathewsUnderstanding Power and the 3 Phases Delta and Wye are a common point of misunderstanding and cause for confusion when understanding and calculating how 3-phase power is used. It is important to understand the difference between the two when they are used with respect to heater design. The three phases of power are […]

Selecting a Regenerative Blower for Process Heater Applications

Regenerative blowers are portable, low-pressure air sources that are ideal for use with many Tutco SureHeat Air Heaters. They provide inexpensive, clean, oil free air, and can be easily mounted on equipment. A blower must be able to provide your desired amount of flow even with the restrictions caused by the heater, plumbing, and manifolding. These […]

What is CA Proposition 65?

What is Proposition 65? Proposition 65 (commonly referred to as Prop 65) is regulation originally passed in 1986 by the citizens of California and its purpose is to alert consumers in California of items which may pose a risk of cancer or birth defects. The State of California maintains a list of these substances and […]

Why Does Watt Density Always Come Up When Discussing Heating Elements?

Overview Watt density is a useful measure when considering the various types of heating elements available. TUTCO-Farnam Custom Products manufactures open coil heating elements which are generally used to heat a gas flow, such as air or nitrogen. We are also manufacturers of surface heaters that heat by conduction. This discussion will pertain specifically to watt density and […]

How Much Wattage Do I Need?

By following a few rules-of-thumb you can determine the wattage requirement for your application. Calculating the wattage requirements to heat a system is a straightforward process as long as all the parameters of heat energy flowing in and out of a system are considered. Heat requirements that must be considered are: Initial heat for the […]

Why use a Diode with a Heater?

Here’s why: Sometimes, when all the design work is done, the heating element is too fragile for either the assembly process, or field operation. This can occur when making a low wattage heater that uses a high voltage. In these cases the element needs to be more robust but the design won’t allow it. One solution is […]

Zoned Versus Distributed Wattage – Definition and Application

Introduction In the heating industry, we are often asked what is the difference between a distributed wattage heater and a zoned heater. These various construction techniques can be applied to many different types of conduction heaters such as cartridge heaters, ceramic and mica strip heaters, and band heaters. Almost any heater that uses a wound coil can use one of these […]

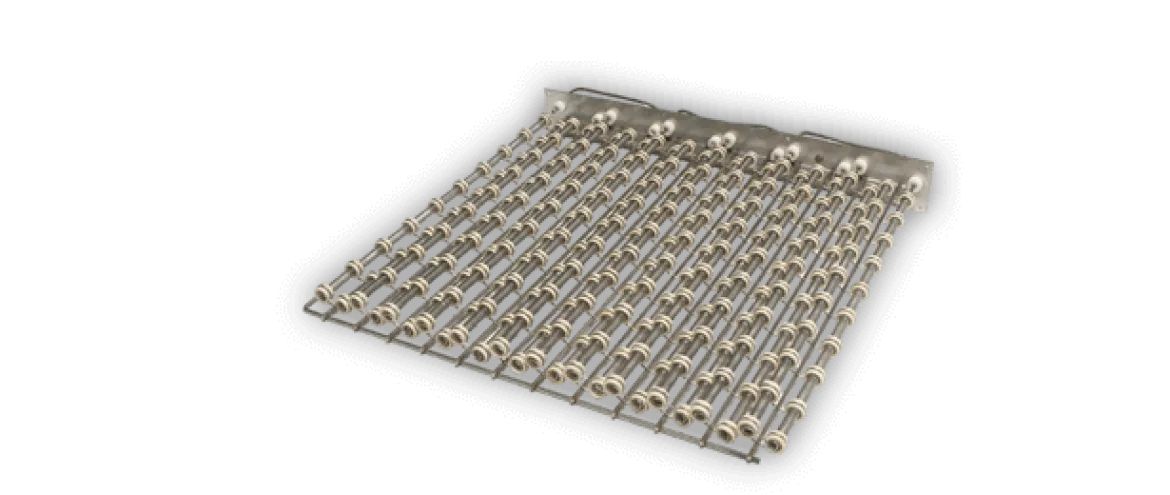

Duct Heaters Overview

Definition As the name implies, duct heaters are generally designed to be installed into ducting. They are usually installed through the side wall to cause the air in the duct to be heated as it flows around and through the open-coil elements. Duct heaters made by TUTCO-Farnam are not for HVAC use. They are for […]

Heat Transfer

Thermodynamics, specifically heat transfer, is used throughout our daily lives, but not always thought of. A common practice of cooking breakfast would be one simple example. You place one type of media, your frying pan, onto a hot surface and apply the “heat”, which is your source of energy, to cook the food. The heat […]

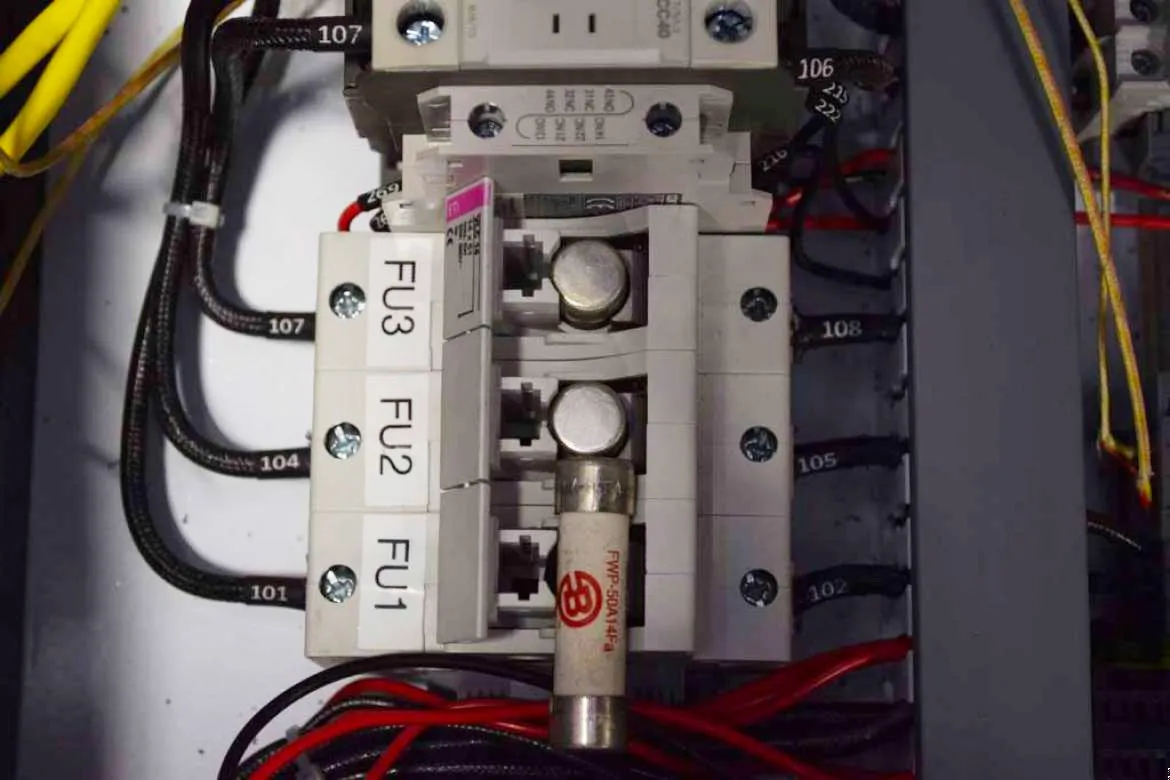

Electric Heating Systems; Branch Circuit Protection

When designing an electric heating system for industrial processes, many factors must be addressed. These factors routinely include required power, location, ducting, air source, and controls, but circuit protection is often overlooked. Proper circuit protection is of utmost importance not only for safety but also to avoid costly downtime and repairs to the system. Electrical […]

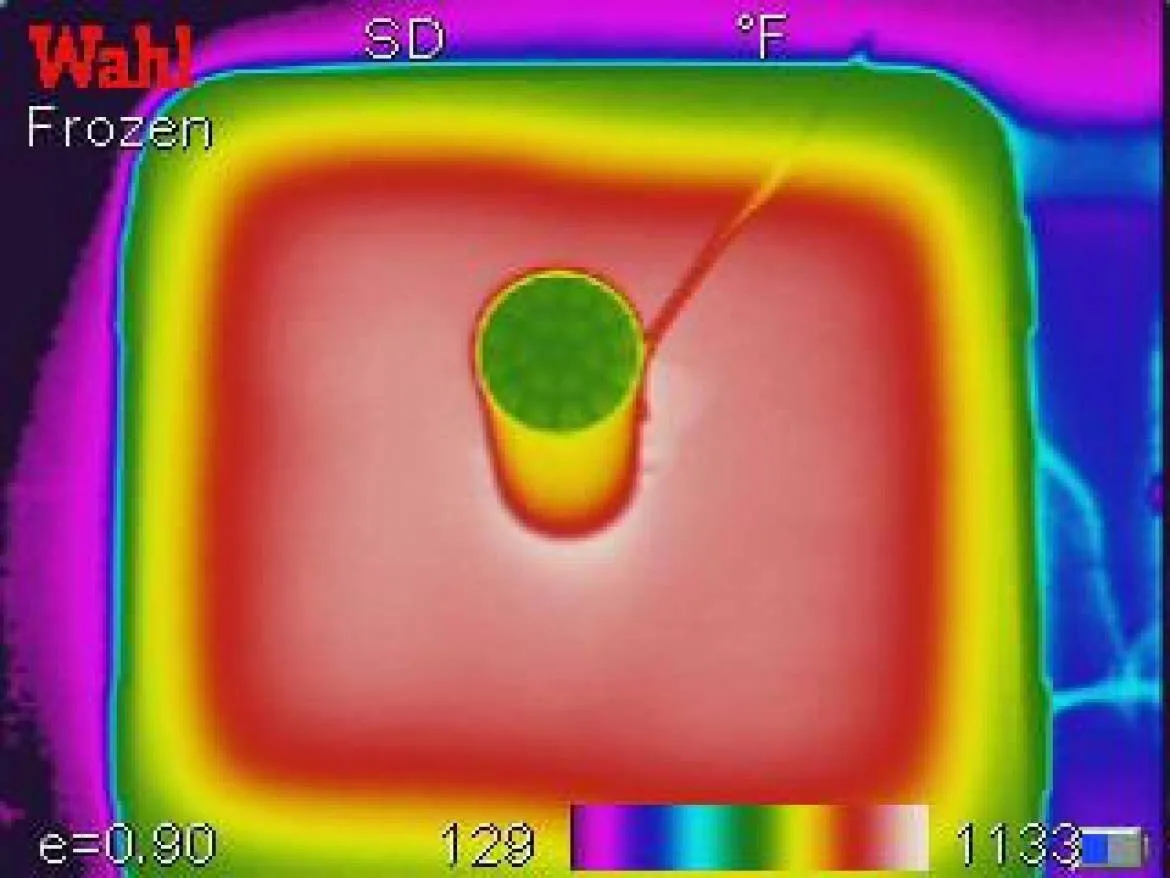

Watts Killing Your Heater?

Once process equipment is designed and placed into service, the importance of each individual component is frequently forgotten. Unfortunately, heaters often find themselves in this situation until there is a failure. Since heaters usually play an integral role within the application, any failure can rapidly expand to a major issue or shutdown. The good news…many […]

SCFM, CFM What’s the difference?

What’s the difference? The majority of TUTCO–Farnam Custom Product’s heaters are used to heat an air flow. When determining the power required to heat a stream of air, invariably two questions will come up. How much “stuff” do we have to heat up? In more technical terms, what is the mass flow rate? How hot […]

Grounding Your Heater

Grounding in GeneralGrounding is often treated as an afterthought, but not all grounds or ground connections are the same. Too often we just assume that any ground connection will be a ‘good’ one. Grounding a device generally serves two purposes. The first is to provide a safe path for current flow in the event of […]

Surface Heaters – an Overview

General As the name suggests, a surface heater is a device that raises the temperature of a surface. Now in the world of heaters, surface heaters aren’t really very sexy – they often consist of little more than a few pieces of mica and some wire. But throw in a thermocouple or a diode and some […]

Estimating the Resistance Wire Temperature for an Open Coil Heating Element

For a typical convection air heating application, the air temperature and the volumetric air flow entering the heating element, and the power produced by the element are known or can be specified. The desired air temperature out of the heating element is achieved by commonly adjusting the power and/or the airflow. A first-order estimate of […]

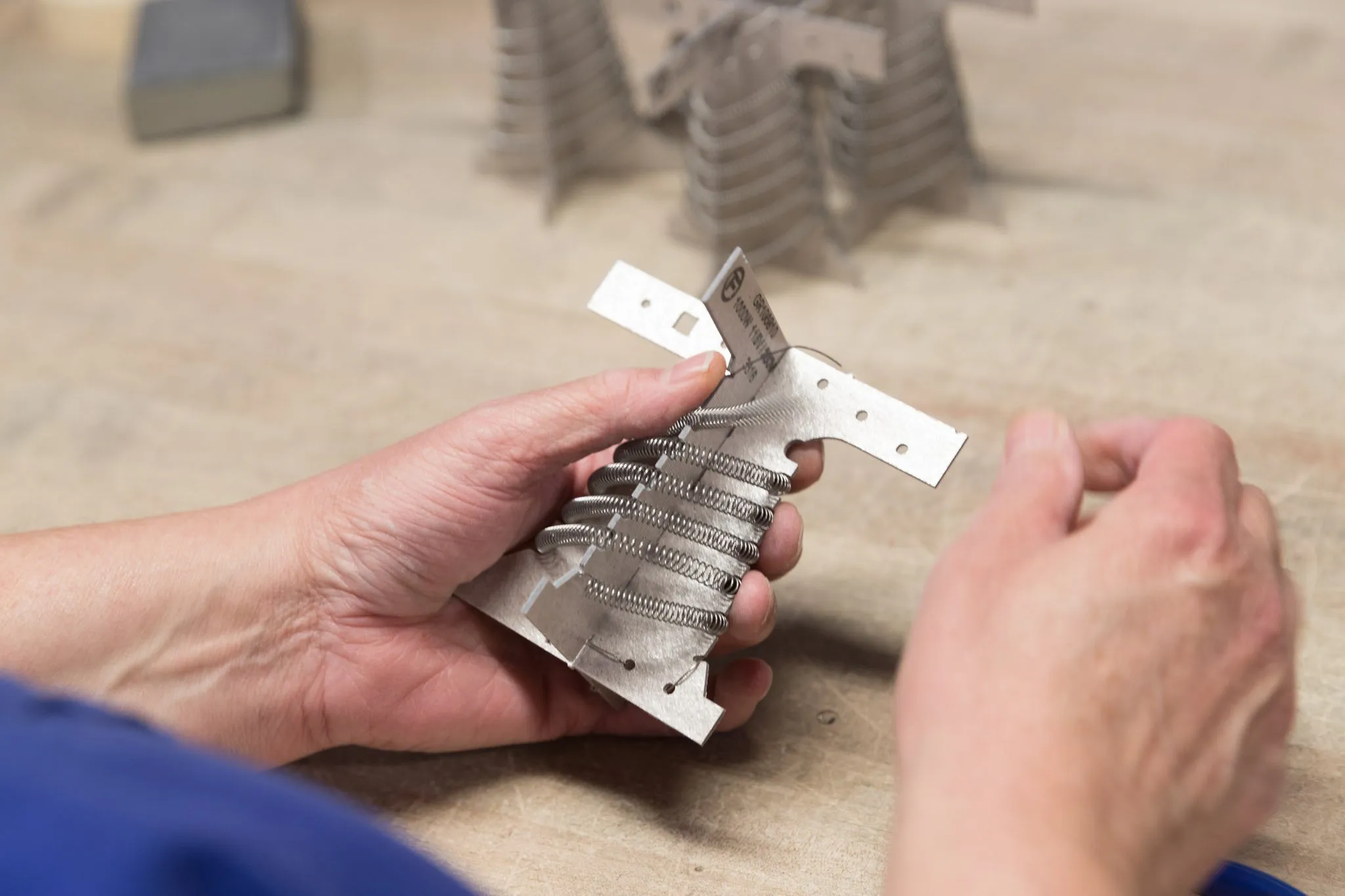

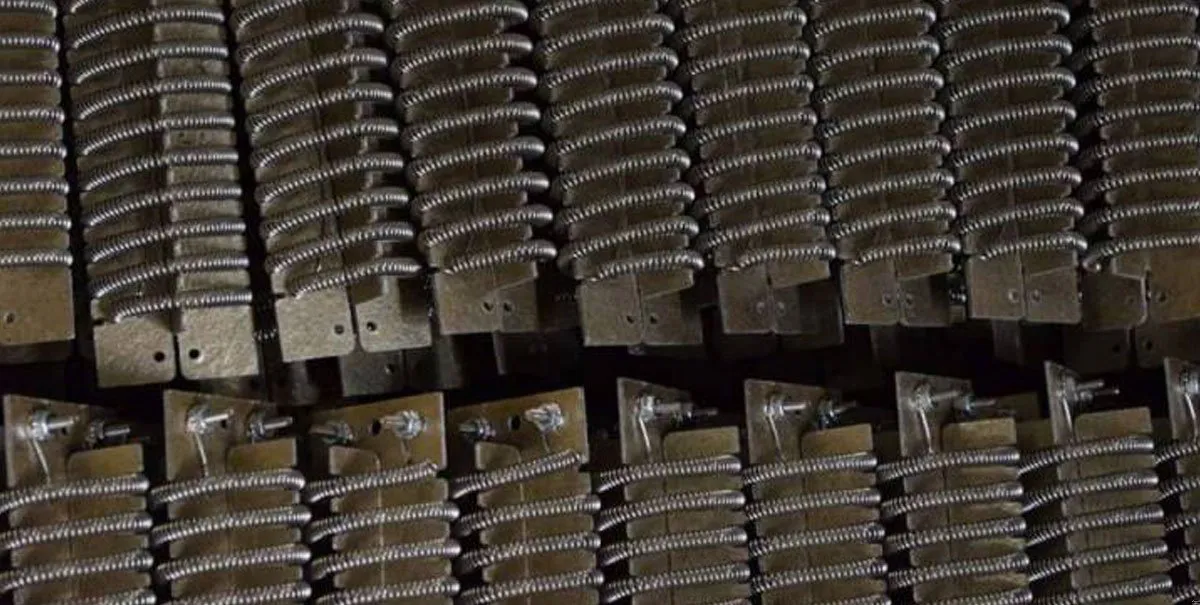

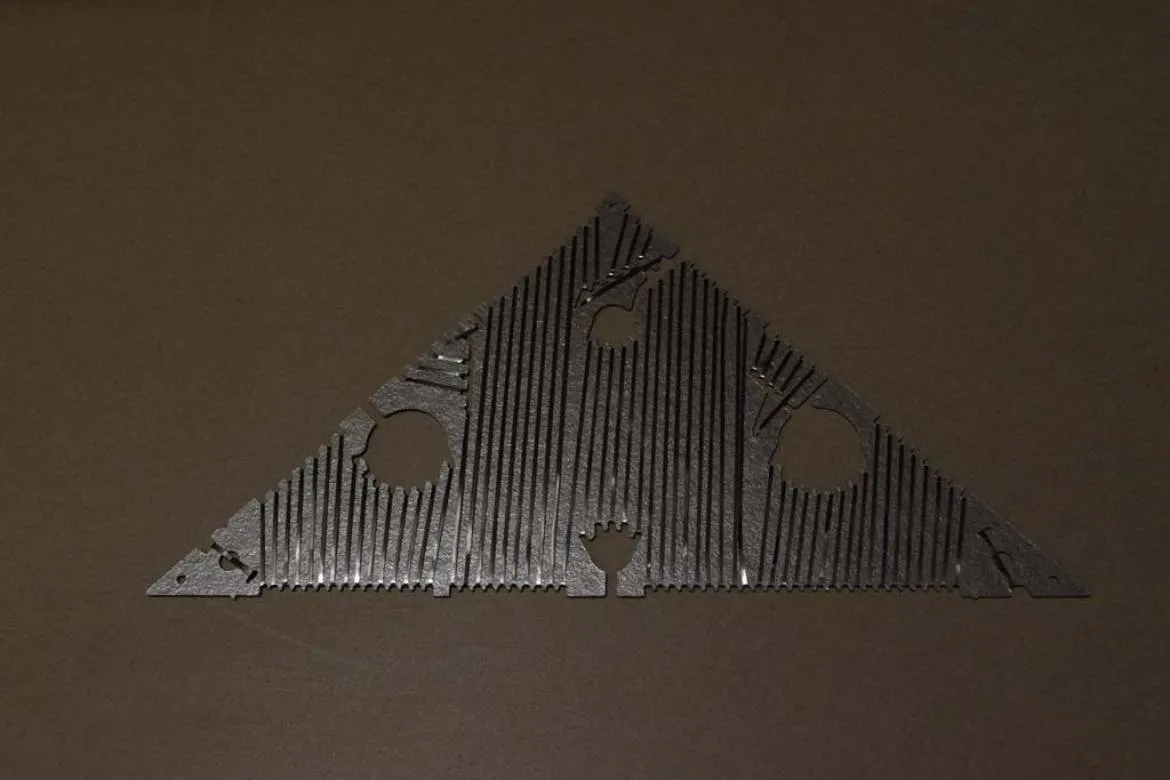

Heater Coil Design

Basic Specifications WattageIn the design of a custom open coil heating element, several factors need to be considered when selecting the optimum coil(s) for an application. First, the watts, volts, and resistance must be determined for each coil in the heater. Typically, the line voltage is specified by the customer and/or end-user. The total wattage […]

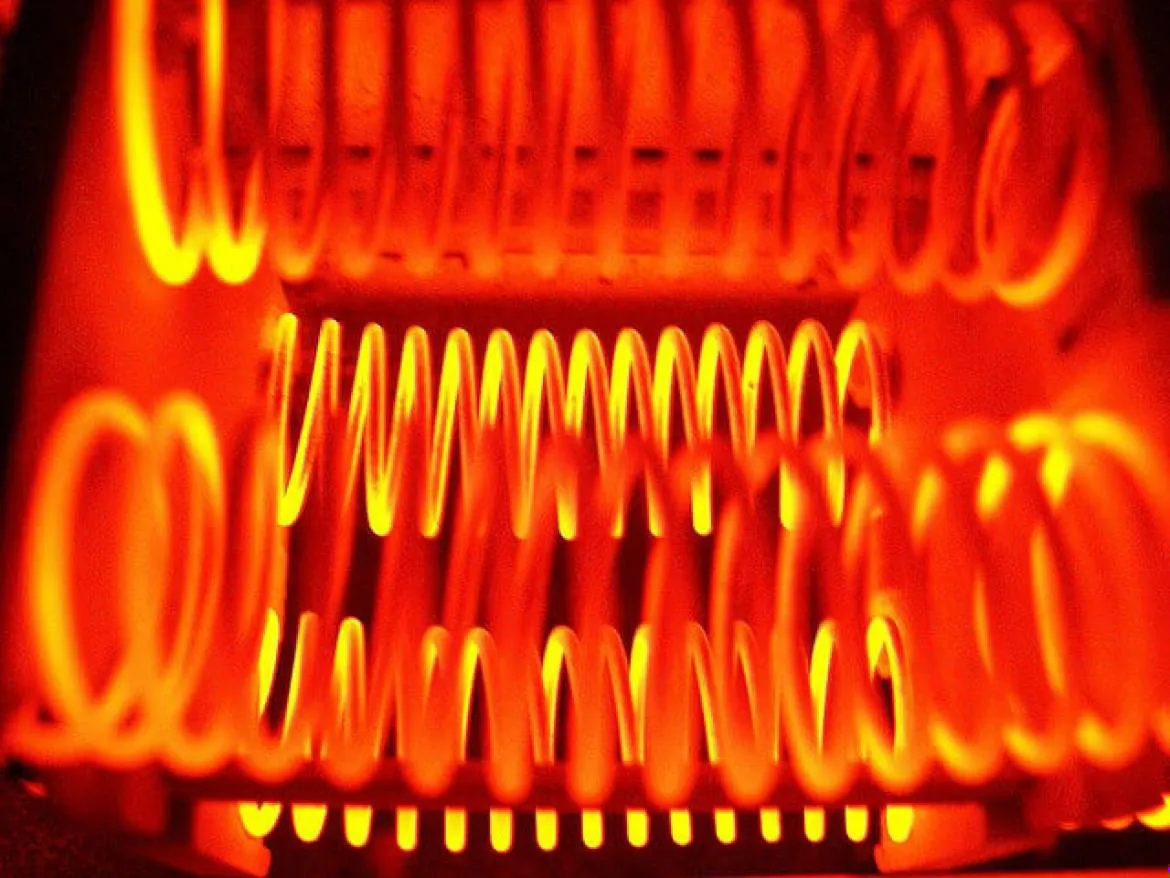

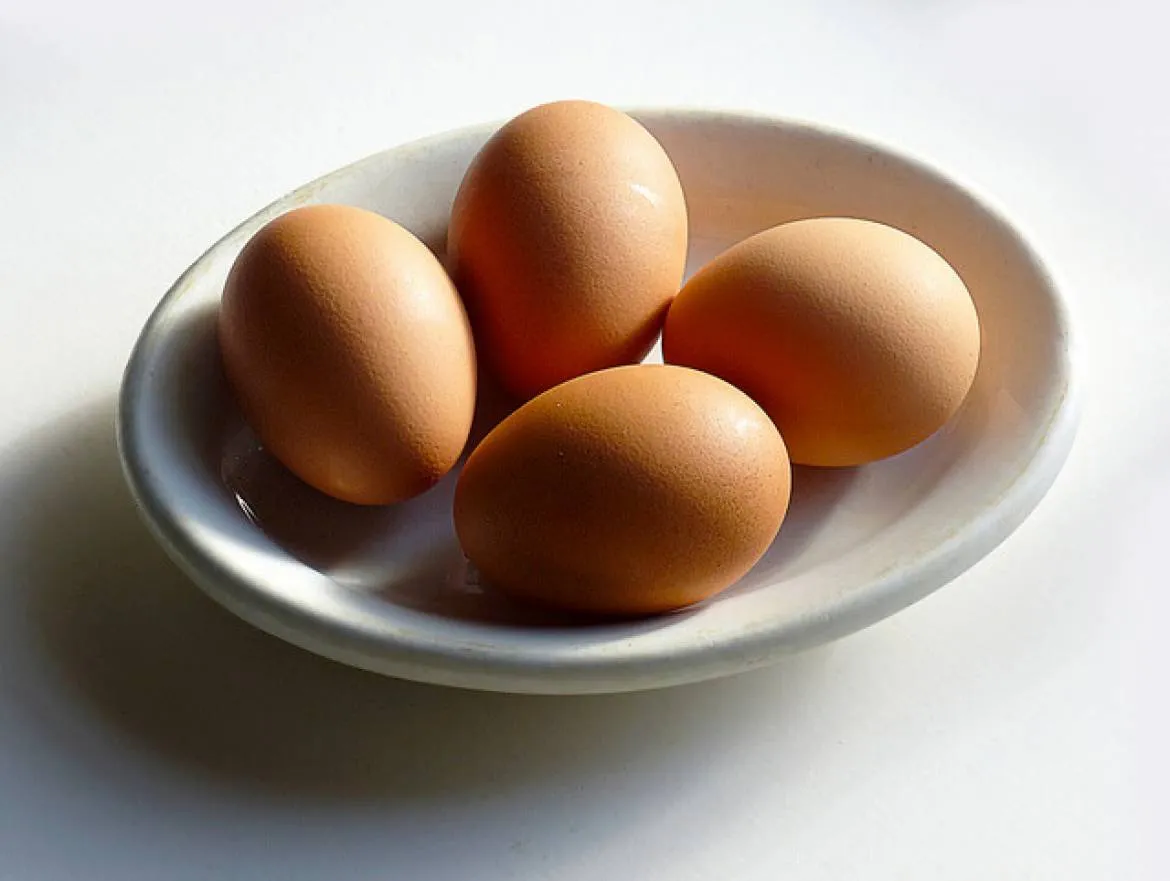

Scrambling an Egg

At TUTCO-Farnam Custom Products, we manufacture many different types of heating products. These heaters are used in all sorts of applications. One of our standard heaters is the Cool Touch 200 (CT200). These Cool Touch heaters are part of the Heat Torch family, which are offered in a variety of diameters. For example, the CT200 […]