Hot Runner Components

TUTCO’s offers the most reliable Hot Runner Components for direct feed and injection molding applications. Our reliable hot runner bushing deliver advanced heater technology and thermocouple protection circuitry.

Precision Series

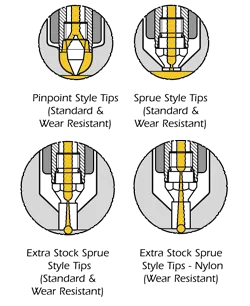

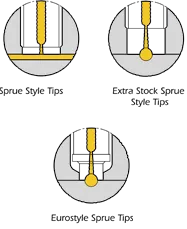

The New Precision Hot Runner Bushings & Nozzles are designed to run mid-size and large molded parts. Advanced heat transfer technology provides optimum performance while a unique sleeve heater design allows for easy and quick replacement. The special tip design allows the Precision to process commodity, engineering and filled resins while drastically reducing tip wear at the gate. The Precision has eleven different gating options to meet a wide range of Direct Feed or Manifold applications.

Features & Benefits

- Exclusive “Flat Gate”™ System

Gate vestige is minimized and each design can be customized - Advanced Integrated Sleeve Heater

Extended heater life for easy serviceability - Unique Wear Resistant Tip Design

Less downtime due to tip repair - Medium and Large Pitch

The Precision can service more mid-size molds/part shot sizes - Consistent Heat Profile

Optimum hot runner performance - Resin Versatility

Wide range of resins can be processed for more applications - Replaceable Tips, Heater and T/C

Easy serviceability - Custom Designed Tip Tools

Easy replacement of all tip styles

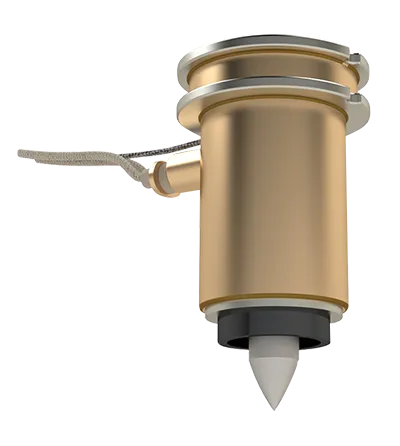

Sprue Bushings

The Integrally Heated Sprue Bushing is uniquely designed for high performance and reliability for Manifold and Direct Feed Applications, even with the most demanding molding cycles and plastic resins. The advanced heat transfer capability is attributed to its integrally heated design, resulting in a more uniform heat profile. A replaceable thermocouple is strategically located close to the melt flow channel for optimization of processing conditions with all thermoplastics.

Features & Benefits

- Graduated Watt Density

Maintains a more uniform heat profile. - High Refractory Insulation

Provides superior heat transfer. - Streamlined Flow Channel

Provides for minimum pressure loss. - Fully Sealed Construction

Maintains highest product reliability. - Made of High Grade Alloy Steel

Increases durability and longer life. - Replaceable Thermocouple

Allows for easy serviceability.

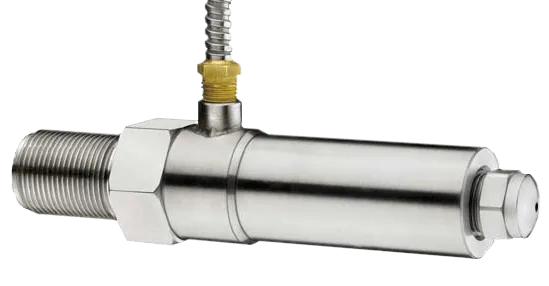

Machine Nozzles

The Integrally Heated Machine Nozzles unique design concept eliminates the voids and air gaps which limit the performance of conventionally heated nozzle systems. The improved heat transfer characteristics of the Sensitip Machine Nozzle provide performance and reliability far superior to any existing nozzle designs.

A replaceable “Type J” thermocouple senses temperature adjacent to the melt channel. This accurate sensing system works in conjunction with a very uniform temperature profile to ensure superior processing of even the most critical of engineering materials.

Features & Benefits

- Integrally Heated Design

Provides optimum nozzle performance. - Streamlined Flow Channel

Provides minimum pressure loss - Fully Sealed Construction

Maintains highest product reliability. - High Grade Alloy Steel Construction

Increases durability and longer life. - Replaceable Thermocouple

Allows for Type “J” or “K”. - Three Tips Styles

Available with either a .500″ or .750″ Spherical Radius, accommodate a full range of Injection Molding applications.

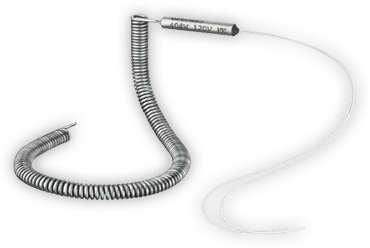

Flextracoil

Our Flextracoil heaters were created to heat flow-through nozzles and sprue bushings in runnerless molding systems.Available in either flat, square or round styles, the Flextracoil can be coiled evenly spaced or with distributed coils.

All styles are stocked uncoiled at Tutco and are formed to customer specifications before shipping.