Conductive

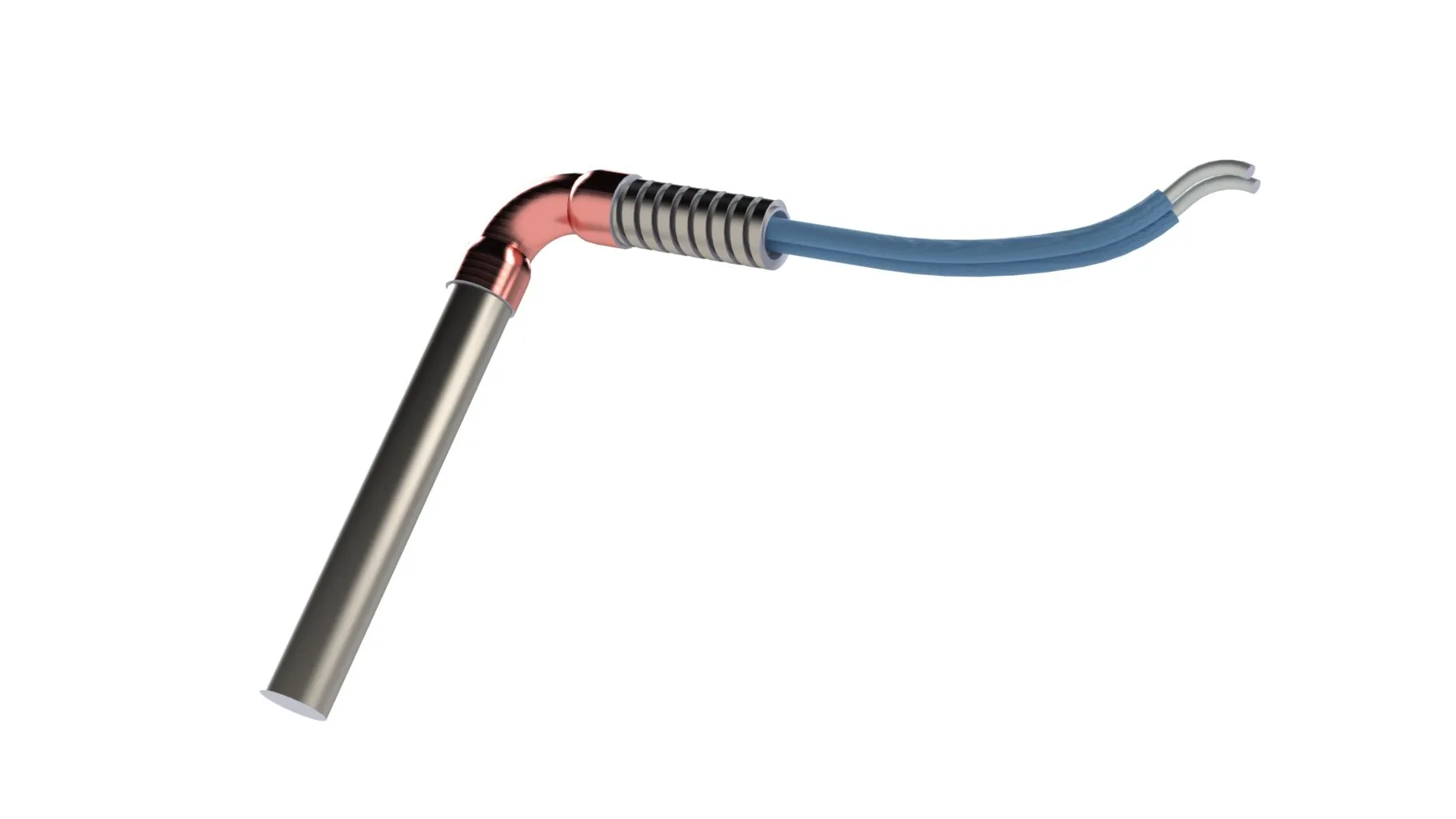

Cartridge Heaters

TUTCO cartridge heaters are available in high-temperature and standard models that provide excellent heat transfer efficiency and a watt density of up to 100 W/in2. Hi-Temp Heaters offer the very best price per performance ratio with the highest number of customizable options. TUTCO electric cartridge heaters are ideal for applications with high heat and excessive vibration characteristics including industrial machines processes like hot stamping, heat-staking, sealing bars, forming and heating platens.

Hi-Temp Cartridge Heaters

An extremely durable swaged insertion product made for high temperature applications. It is made to withstand a sheath temperature of up to 1400 °F (760°C), internally up to 1600°F (871 °C). Its swaged construction provides superior heat transfer and resistance to vibration.

Standard Cartridge Heaters

TUTCO also stocks many standard heaters with a maximum sheath temperature of 1000°F (538°C). Dual voltage and three-phase options are available on select diameters. TUTCO engineers can work with you to design and manufacture custom cartridge / insertion heating solutions in multiple shapes, lengths, connectors and with distributed or zoned wattages.

Stocked Cartridge Heaters

TUTCO stocks high quality popular sizes to fit most conductive insertion heated applications. With a maximum sheath temperature of 1000°F (538°C), they offer superior heat transfer and durable long-lasting life.

APPLICATIONS

PLASTICS

Compression Molding

Blown Film Processes

Blow Molding Machines

Plastic Pellet Dryers

PACKAGING

Platen Heaters

Packaging and Sealing Bars

Form Fill Packaging Machines

PROCESS

Textile Processing

Chemical Processing

Laboratory Warmers

Bolt Heaters

Laminating Applications

Scientific Testing Equipment

3D Printers

Plastic Pipe Cutting / Joining

Glass Processing

FOOD SERVICE

Food Grade Sealing/Wrapping

Food Service Warming

Refrigeration

TRANSPORTATION

Automotive Applications

Space Heaters for Public Transport

Agriculture Transportation

MORE APPLICATIONS

Holding Tanks

Drum & Barrel Heating

Battery Warmers

Deicing Applications

Defrost Heaters

Cryogenic Applications

RV Water Heaters

Control Panel/Enclosure Heater